Blog

Ionotropic gelation: the benefits of encapsulating functional active ingredients

Ionotropic gelation is one of the most effective micro-encapsulation techniques used to protect and deliver functional active ingredients.

It is a process based on the interaction between ionic polymers and oppositely charged ions that gives rise to a cross-linking phenomenon, resulting in the formation of spherical hydrogels capable of trapping hydrophilic and lipophilic components.

How ionotropic gelation works

The principle is simple yet highly effective. An aqueous solution containing an ionic polymer, such as sodium alginate, and the substance to be encapsulated is dripped into a bath rich in divalent ions (e.g., calcium Ca²⁺).

The positively charged ions bind to the carboxyl groups of the polymer, forming a stable three-dimensional network known as the hydrogel. In this way, the active substance remains trapped within the microcapsule.

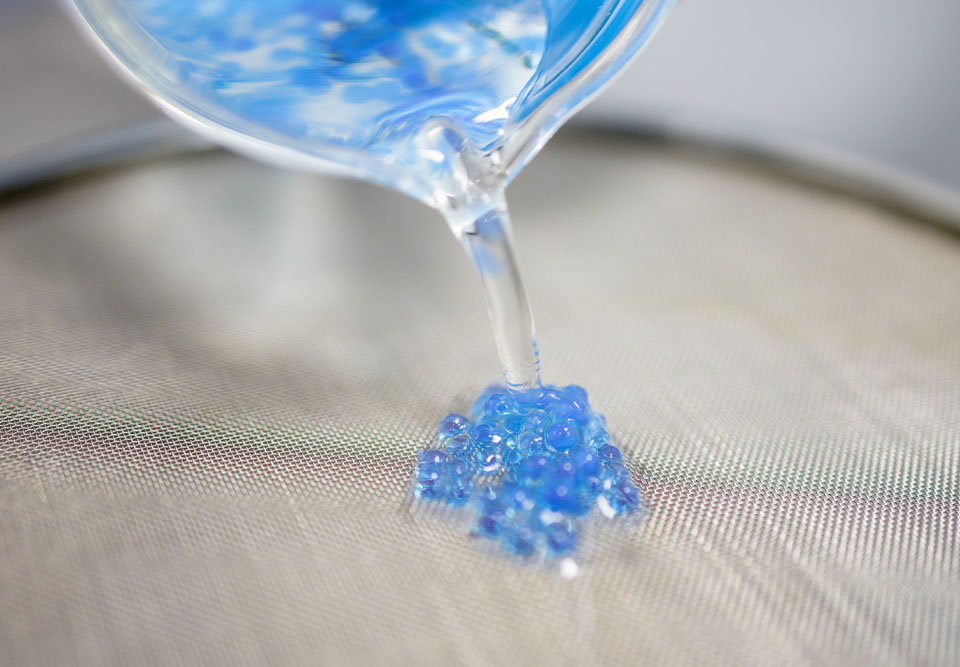

The result? Spherical hydrogels with diameters ranging from 20 to 1000 µm, capable of containing up to 70-80% of the active ingredient, without resorting to thermal processes that could damage the more delicate ingredients.

Ionotropic gelation – Sphera Encapsulation

The benefits of microencapsulation via ionotropic gelation

Choosing this technology means taking advantage of numerous advantages:

• Simplicity of the method and high reproducibility.

• High payload: ability to transport large quantities of active ingredient.

• Good organoleptic characteristics with the ability to mask unwanted odors and flavors.

• Gentle process, which does not require high temperatures.

• Protection of the active ingredient from external factors such as gastric acidity, oxidation, or degradation.

• Controlled and targeted release, useful in nutraceutical, pharmaceutical, and cosmetic applications.

These advantages translate into concrete applications across various industrial sectors, from food to cosmetics.

Ionotropic gelation – Sphera Encapsulation

Applications in food, nutraceuticals, and cosmetics

Ionotropic gelation is widely used in various sectors:

• Food: protection of flavorings, vitamins, probiotics, and minerals.

• Nutraceuticals: encapsulation of bioactive ingredients and supplements to improve their bioavailability and absorption.

• Cosmetics: gradual release of functional ingredients in creams, serums, and personalized treatments.

This is where the experience of Sphera Encapsulation comes into play, a leading Italian provider of innovation in the field of microencapsulation.

Ionotropic gelation – Sphera Encapsulation

Sphera Encapsulation: research and development at the service of innovation

The first Italian company entirely dedicated to research and development in encapsulation technologies, Sphera Encapsulation works to make these solutions increasingly accessible and practical.

Thanks to its expertise and scientific knowledge, the company can design innovative microencapsulation systems tailored to customer needs.

Discover how ionotropic gelation can transform your encapsulation projects.

If you want to develop customized solutions with ionotropic gelation technology, Sphera Encapsulation is the ideal partner.

Contact us to discuss opportunities in the food, nutraceutical, or cosmetics sectors.

Stay up to date with our activities and discover the latest news by following us on our social media channels.