Blog

Spray Chilling: Technology and Its Uses in Cosmetic Formulations

In the advanced cosmetics sector, the use of encapsulation technologies is a key element for improving the stability, efficacy, and bioavailability of active ingredients.

Among the most promising methodologies, Spray Chilling (or Spray Cooling) technology stands out for its versatility, cost-effectiveness, and ability to protect sensitive molecules from potentially degrading environmental or process conditions.

At Sphera Encapsulation, the first Italian company entirely dedicated to research and development in encapsulation technologies, we study and optimize Spray Chilling as a functional and scalable solution for the production of nanocapsules and solid particles for various cosmetic formulations.

Principles and Operation of Spray Chilling Technology

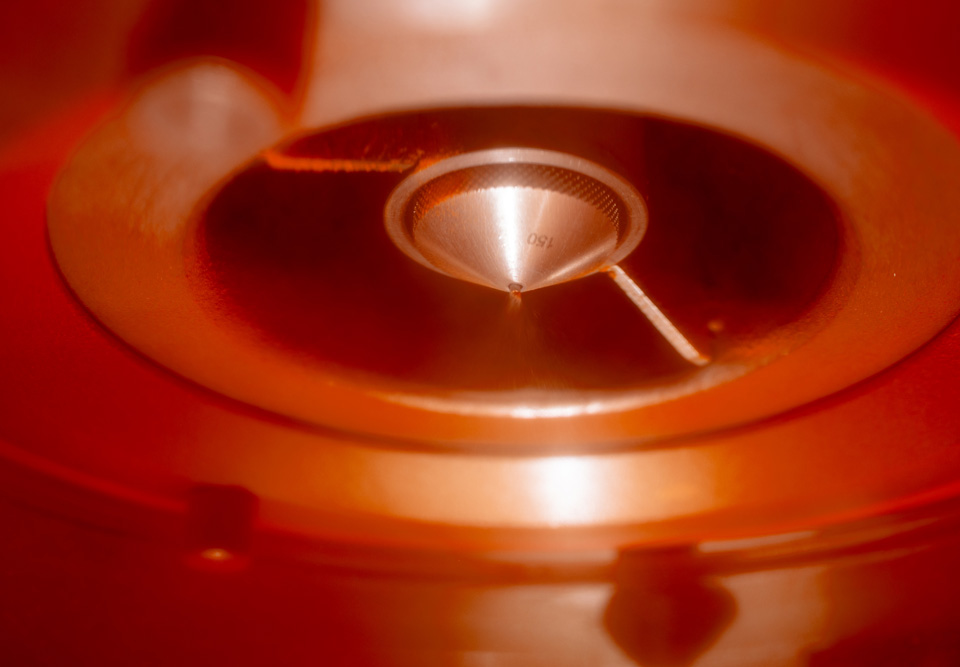

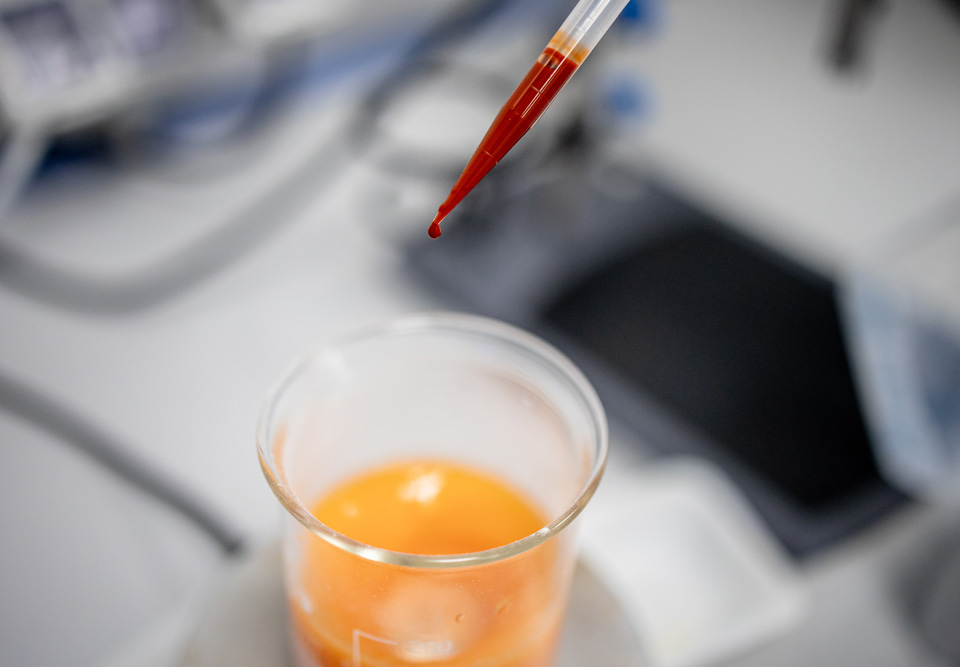

Spray Chilling technology is based on the atomization of a molten mixture, composed of a lipophilic carrier material (such as waxes or solid triglycerides) and the active ingredient to be encapsulated, in a temperature-controlled cooling chamber.

During atomization, molten material droplets are nebulized and rapidly solidified by cooling, resulting in solid particles or powders of variable size (ranging from a few microns to hundreds, depending on the process parameters).

These microparticles or nanocapsules serve as controlled-release systems, protecting the active ingredient during storage and modulating its availability once applied to the skin or incorporated into a cosmetic formulation.

Materials and Critical Process Parameters

In the spray chilling encapsulation process, the selection of the encapsulating material is crucial.

The following are mainly used:

- Natural or synthetic waxes, such as beeswax or carnauba wax.

- Solid triglycerides, such as hydrogenated glycerides of fatty acids.

- Biodegradable lipid derivatives, compatible with lipophilic or amphiphilic active ingredients.

The melting temperature of the carrier material, the atomization speed, and the temperature of the cooling chamber are key parameters for determining the morphology, particle size distribution, and encapsulation percentage of the active ingredient.

Careful management of these variables enables the production of highly uniform solid particles with high loading efficiency and optimal stability.

Applications in the cosmetics field

Spray chilling is widely used in the development of functional cosmetic formulations due to its ability to protect and deliver sensitive active ingredients.

The solid particles obtained with this technology can be used in:

- Face and body emulsions and creams, to improve the thermal and oxidative stability of antioxidants and fragrances.

- Makeup and compact powders, to achieve the controlled release of pigments or moisturizing agents.

- Anti-aging and sun treatments, where the protection of lipophilic active ingredients is essential to maintain their effectiveness.

- Cleansing products and solid cosmetics, thanks to its good compatibility with waxy or lipid matrices.

This economical encapsulation technology represents a valid alternative to more complex methods (such as spray drying or coacervation), while maintaining high levels of control over the morphology and functional properties of the particles.

Technical Advantages of Spray Chilling

The adoption of Spray Chilling encapsulation technology brings a series of technical benefits relevant to cosmetic and industrial research:

- Increased stability of active ingredients: reduced oxidation, volatility, and photochemical degradation.

- Protection of sensitive compounds: ideal for pigments, aromas, antioxidants, and fragrances.

- Improved absorption: lipid encapsulation promotes the skin penetration of lipophilic and amphiphilic active ingredients.

- Organic solvent-free process: environmentally friendly and safe for natural cosmetic formulations.

- Industrial scalability: easily adaptable from laboratory to large-scale production.

Thanks to these characteristics, Spray Chilling is positioned as an efficient and sustainable encapsulation technology, capable of combining functional performance and process cost-effectiveness.

Sphera Encapsulation’s approach: research, development, and innovation

At Sphera Encapsulation, we place scientific study and applied experimentation at the heart of our work.

Our multidisciplinary team studies the interaction between encapsulating materials, process parameters, and active ingredient stability to optimize the performance of our partners’ cosmetic formulations.

Using Spray Chilling technology, we develop customized nanocapsules and solid particles for various applications, aiming to improve the efficacy, stability, and sensorial experience of finished cosmetic products.

If you’d like to develop new encapsulation projects or explore the potential of Spray Chilling in your research or production area, please contact us.

We collaborate with companies and laboratories to transform ideas into concrete, high-performance solutions.

Stay up-to-date on encapsulation technologies.

At Sphera Encapsulation, true innovation comes from the dialogue between science and application.

For this reason, we invite you to follow us on our social media channels and stay updated on our research projects, new encapsulation technologies, and advanced applications of Spray Chilling in the cosmetics field.